GPower ProFactory

Et modulært og skalerbart testsystem til alle former for testafvikling

Hvad er ProFactory?

ProFactory er en all-inclusive test- og automatiseringsløsning, som kan bruges til produktionsfaciliteter, R&D-afdelinger og laboratorier. En software- og hardwareplatform, der kan gå fra at blive implementeret på en enkelt computer til at dække et globalt selskab.

ProFactory konverterer jeres knowhow og eksisterende hardware til moderne testudstyr, controllere eller automatiseringsenheder. ProFactory-stationer er kendetegnet ved, at de er netværksaktiverede, centralt styrede og fjernovervågede. Derudover understøtter de manuel og halvautomatisk betjening af operatører, men kan også være fuldt integreret i automatiserede inline- eller robotstyrede miljøer.

ProFactory er standardiseret til at tilbyde jer alle de professionelle funktioner, som I ville ønske, at I selv havde tid til at implementere. Som resultat heraf sparer I både en masse tid og penge, hvilket sker allerede fra første implementering – og hver dag, I bruger det.

Hvorfor ProFactory?

1: Spar tid i hverdagen ved at automatisere testoperationer

Tid er blandt de vigtigste parametre i forhold til at være konkurrencedygtig! Med ProFactory sparer I tid i alle jeres operationer. For eksempel gør testudvikleren jer hurtigere klar til at teste produkter, både når det gælder nye produkter og varianter af eksisterende. Derudover kommer jeres testtekniker også til at bruge mindre tid på planlagt og ikke-planlagt vedligehold, hvilket giver mere tid til reel produktion, da man undgår afbrydelser.

Jeres stationer vil desuden være meget mere fleksible, hvilket resulterer i bedre udnyttelse af udstyret, mindre nedetid og flere valg i forhold til at flytte funktioner rundt i jeres fabrik.

2: Spar penge ved at standardisere uden at give køb på fleksibilitet

Vedligeholdelse af eget, brugerdefinerede udstyr er dyrt, da man betaler for funktionsudvikling, løbende forbedringer og arbejdstimer, herunder videreuddannelse og træning af ens personale.

Resultatet er ofte ineffektivt udstyr, og at de ønskede funktioner aldrig implementeres. Derudover lever man også med daglige problemstillinger, der aldrig rigtig bliver løst, dels fordi det er tidskrævende, men også fordi det er for dyrt at gøre mere end ”bare” det vigtigste. Ved at standardisere jeres udstyr deler I disse udgifter med mange andre – og med ProFactory kan I standardisere uden at opgive fleksibilitet!

3: Forbedre jeres produktkvalitet ved at teste korrekt hver eneste gang

ProFactory styrer mange aspekter af jeres teststationer, der har direkte indflydelse på produktkvaliteten. Det betyder blandt andet, at det er meget mindre sandsynligt, at I kører en forkert test eller en test med forkerte testparametre.

Med ProFactory kan I reducere negative effekter på jeres produkter under gentagne tests, ligesom I også kan udnytte jeres instrumenter til fulde – selv når I tester prototyper!

4: Mist aldrig data igen med automatisk synkronisering og komplet sporingshistorik

ProFactory dokumenterer og sporer automatisk alle vigtige aspekter af jeres test: Alt fra miljøparametre til en komplet changelog.

Med guidet betjening, central styring af konfiguration og synkronisering er jeres testkvalitet i top. Derudover sikrer fjernovervågning og central resultatindsamling, at I aldrig mister vigtige data igen.

Hvordan bruges ProFactory?

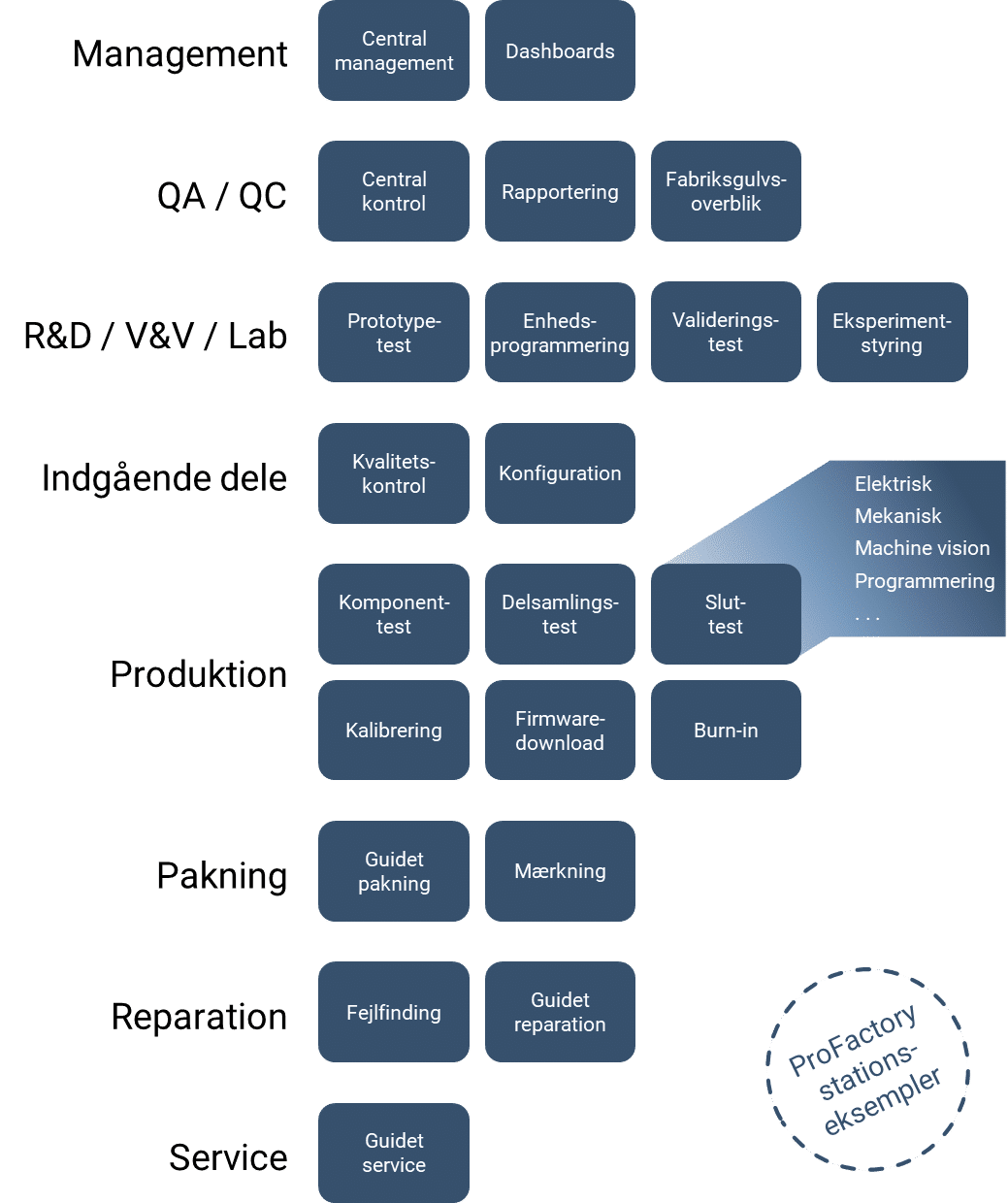

For at lade jer oprette, administrere og synkronisere ProFactory-konfigurationer er ProFactory-softwarekomponenter Supervizer, Devizer og Provider installeret på hver computer, der er en del af jeres ProFactory-netværk. På funktionelle stationer installerer vi også teststyringssystemet TestStand fra National Instruments, som nemt og hurtigt integreres med ProFactory. Med denne standardiserede og kraftfulde software kan vi bygge enhver funktionel station til manuel eller automatiseret brug – nedenfor vises nogle almindelige applikationsområder.

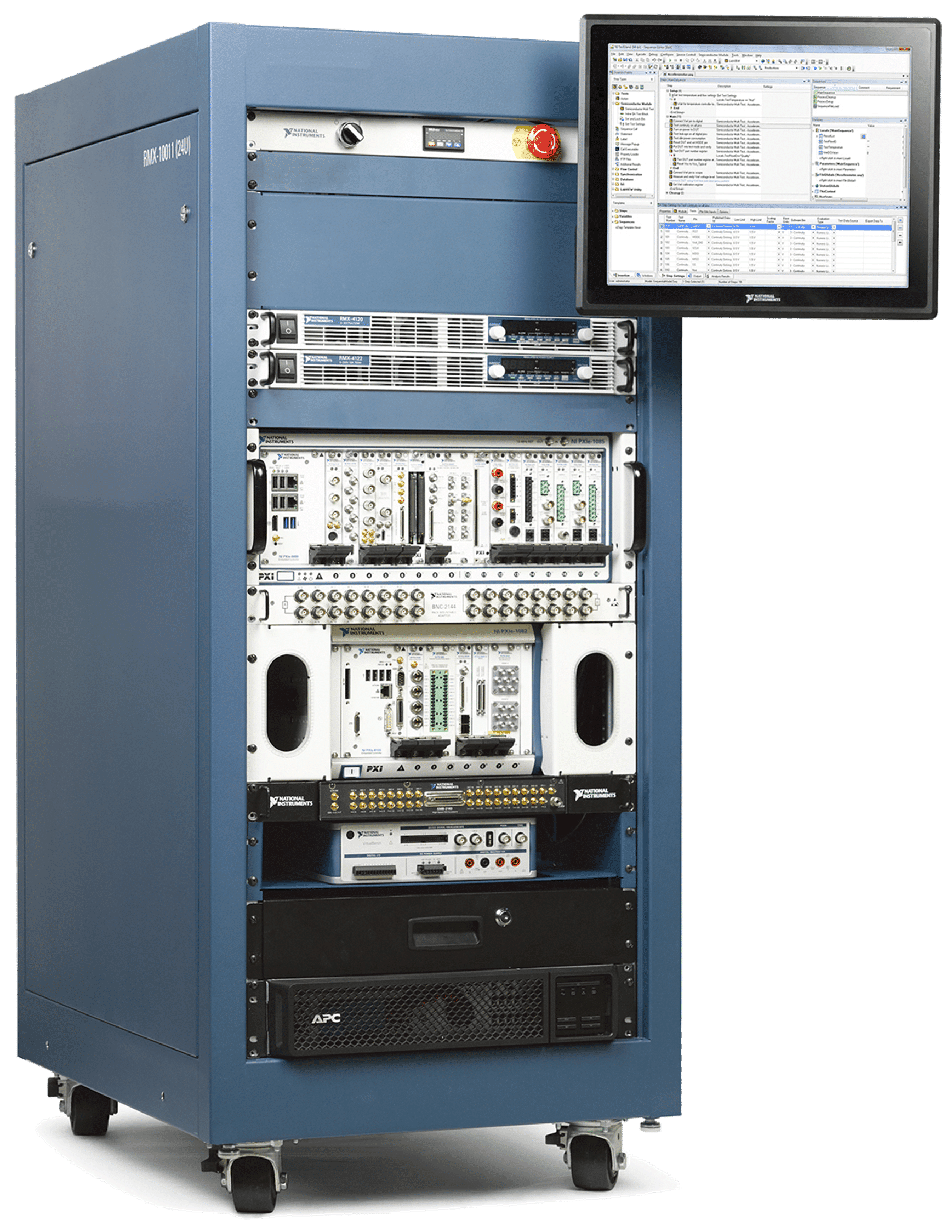

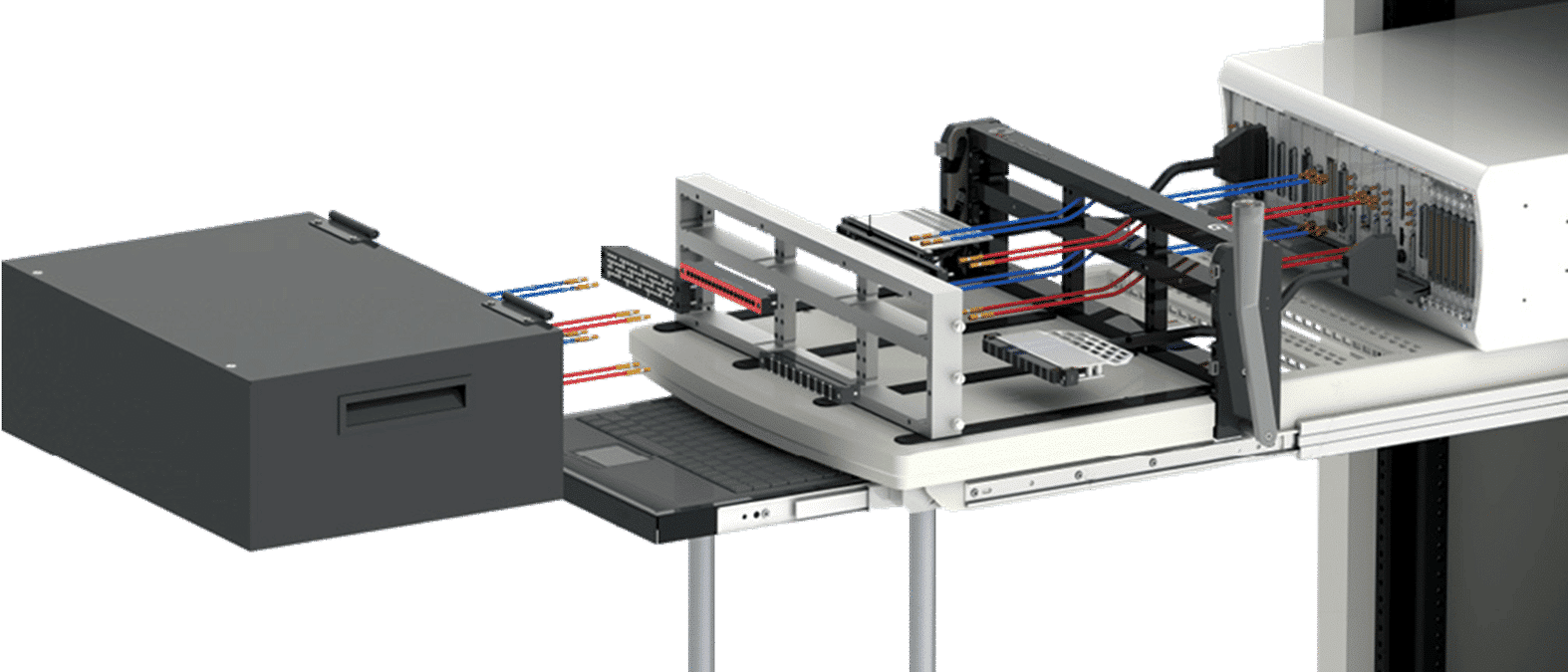

Nogle automatiseringsopgaver kræver kun en computer, mens andre kræver mere hardware, såsom kabinetter med instrumenter og kontrolsystemer, scanningsudstyr eller grænseflader til andre enheder eller til jeres produkter. Vi kan levere en ProFactory-station til enhver automatiseringsapplikation.

Et udsnit af use-cases

Har I mange stationer, der kører hver sit testsystem?

Mange produktionsvirksomheder gennemgår en udvikling, hvor mængden af teststationer stiger i takt med mængden af produkter – og ofte med hver sit testsystem. Dette gør testafviklingen meget kompleks, og giver store udfordringer med versionsstyring. Resultatet er ofte, at udviklere bruger al tiden på at vedligeholde de eksisterende systemer i stedet for at optimere testafviklingen.

Med ProFactory får I en fælles ramme, hvor I nemt kan styre testsekvenserne. Teststationerne synkroniseres automatisk med en fælles database, som er det fælles indgangspunkt for både udviklere og teststationer.

Brug modulære test til at genanvende teststationer

Når reklamationer skal håndteres, indgår der næsten altid en test af den påståede fejl. Nogle gange kan det klares med en visuel inspektion, mens det andre gange kræver en grundigere test af elektronikken. Oftest vil man kunne genanvende en teststation, men hvis ikke testsekvenserne er udviklet fleksibelt, kan det blive en større udfordring.

Løsningen kan være at bruge modulære test, hvor en operatør kan udvælge dele af testen, der skal udføres. På den måde sparer man blandt andet tid på testafvikling, reducerer vedligehold af testsekvenser, og slipper for at udvikle en ny teststation.

Teststationer fordelt på mange lokationer

I en moderne virksomhed er produktionen ofte fordelt på flere lokationer og mange gange også i flere lande. Det kan derfor være svært at sikre optimal testafvikling på tværs af landegrænser, da omgivelserne kan være svære at replikere, ligesom det også kan være vanskeligt at skaffe data til at dokumentere forskellene.

Med ProFactory bliver alle relevante data automatisk logget til en eller flere databaser, som er let tilgængelig overalt. Det gør det blandt andet nemmere at identificere parametre, der påvirker udfaldet af testen – og dermed også nemmere at optimere testafviklingen.

ProFactory software

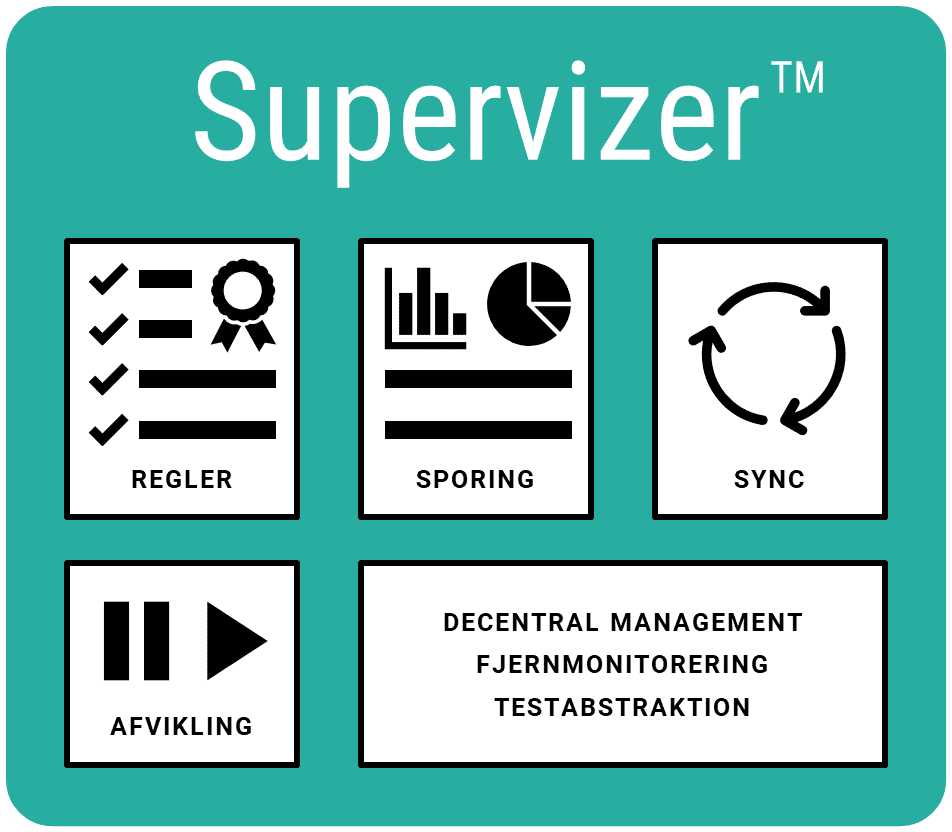

Hvad er Supervizer?

Supervizer sikrer, at I laver jeres testprocesser på den rigtige måde. Derudover maksimerer den oppetid og udstyrsværdi. Det sker ved, at Supervizer styrer jeres stationer og testkonfigurationer for at sikre, at I altid kører den rigtige test med de rigtige parametre.

Supervizer tilbyder desuden avancerede kontrolmuligheder såsom delvise tests og suspendering samt senere genoptagelse af test, som muliggør en dybdegående sporing af jeres testproces og -miljø. Yderligere tilbyder Supervizer også central konfiguration, automatisk resultatopsamling og fjernovervågning af jeres stationer.

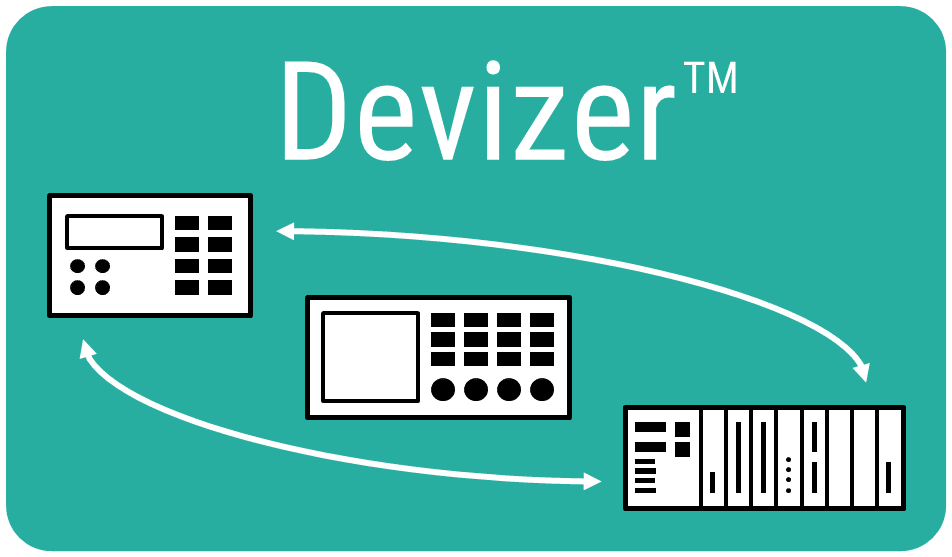

Hvad er Devizer?

Devizer er den intelligente instrumentdriver, der gør det muligt at oprette en testsekvens og bruge den til alle produktvarianter med forskellige hardware på forskellige teststationer.

Devizer tilbyder en unik hardware-abstraktionsstrategi med abstraktion af funktioner og kanaler i stedet for instrumenttype. Med funktioner som testvalidering, instrumentsporing og parameterisering af instrumentegenskaber tilbyder Devizer instrumentdrivere unik værdi, og egner sig perfekt til brug i testsekvenser, der er oprettet med teststyringssoftwaren NI TestStand. Opret Devizer-instrumentdrivere funktion efter funktion eller køb ready-to-run Devizer-drivere fra GPower.

Hvad er Provider?

Provider er den softwarekomponent, der lader ProFactory identificere og beskrive jeres UUT (Unit Under Test), som sker på en standardiseret måde. En fysisk UUT skal altid have et serienummer, men den kan også være en variant af et produkt, som igen kan være en del af en kategori, men variant og kategori er valgfrie.

ProFactory hardware

Stationer

Vi tilbyder turn-key-stationer af enhver art: Fra enkelte instrumenter til fritstående eller indbyggede kabinetter.

Stationer bruges i mange forskellige situationer, men hvor typiske eksempler kunne være teststationer (elektrisk, mekanisk, komponent, PCBA), inspektionsstationer (service, kvalitet, defekter), konfigurationsstationer, maskinstyringsudstyr, kalibreringsstationer, guidede handlinger (pakning, service, reparation), udstyr til machine vision og udstyr til dataindsamling og mobildrift.

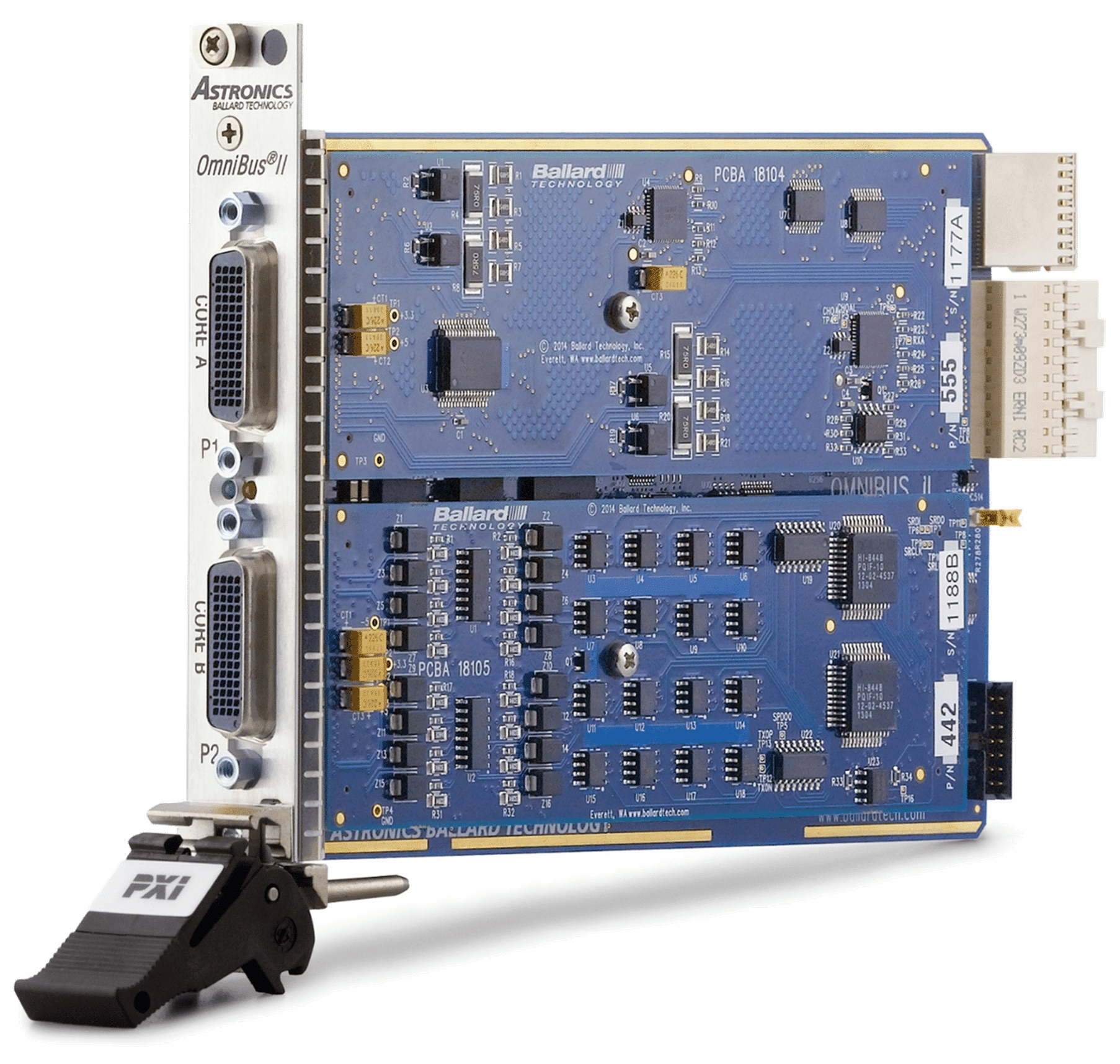

Instrumenter

GPower kan levere ethvert kommercielt instrument på markedet. Det kunne for eksempel være måleenheder, signalgeneratorer, strømforsyninger, controllere, industrielle interfaces og kommunikationsenheder.

Vi har know-how til at hjælpe dig med at vælge det rigtige instrument. Vi kan levere forudbyggede Devizer-drivere til mange almindelige instrumenter, men kan også bygge en, hvis driveren ikke allerede findes.

Fixturer

Fiksturer er typiske UUT-forbindelseskomponenter og bruges til platformdesign. Eksempler på fiksturer kunne for eksempel være:

- Fiksturidentifikation

- Tilslutning til fiksturforbindelse og -handlinger

- Overvågning af fiksturtemperatur

- In-fixture UUT-identifikation

- In-fixture instrumenter og enhedsprogrammering

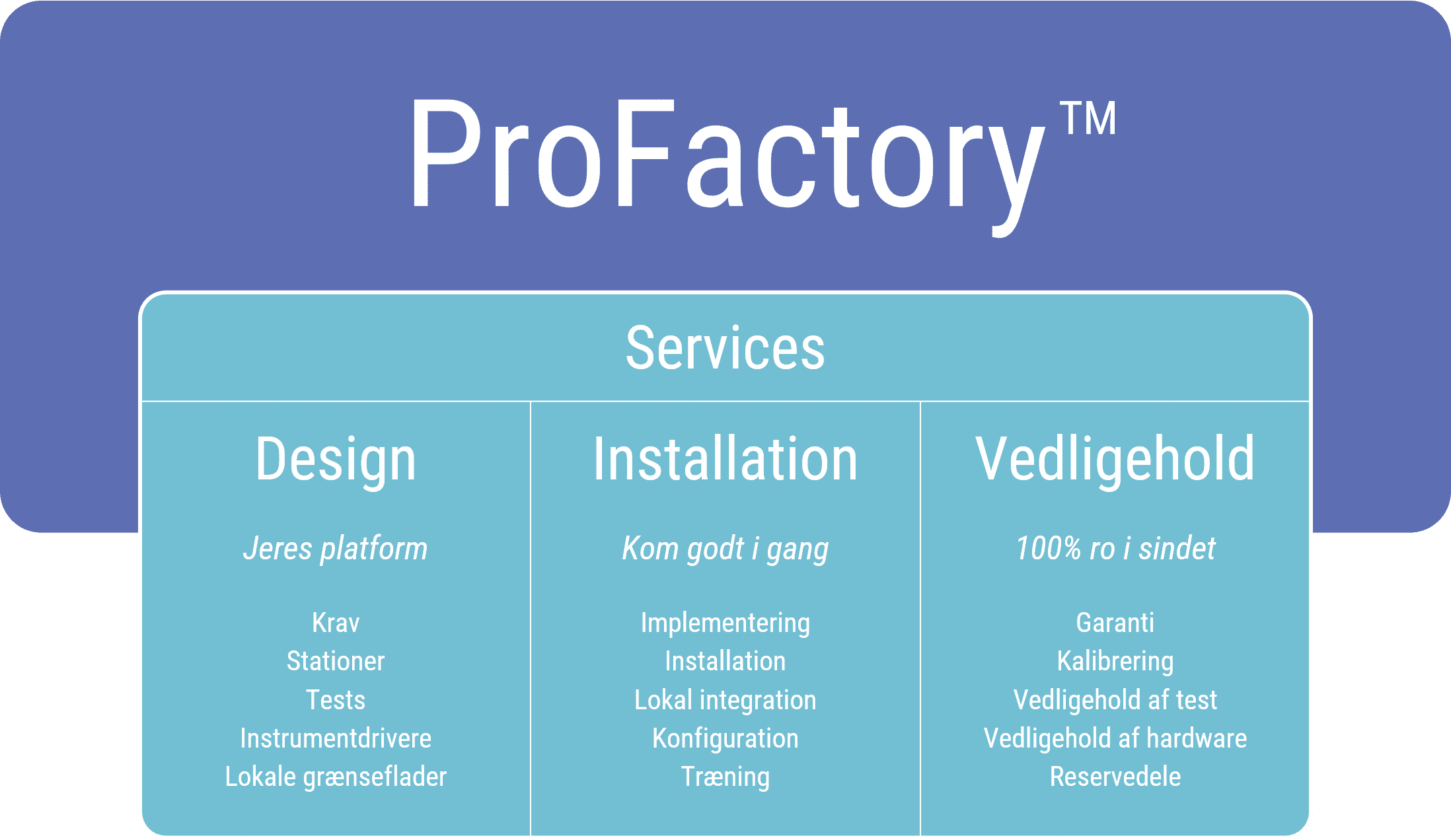

ProFactory services

Interesseret i at høre mere?

Vil du vide mere om pris og funktionalitet? Ring til os direkte på +45 5190 5790, eller indsend en formular. Vi vender tilbage i løbet af 24 timer.