Two State-of-the-art IO-Link Products in the Same Office Building!

In most cases, you go online to find information about new products and interesting theories. A Google search or skimming a newsletter, and we're fast forward. But as we also know, it’s sometimes the informal conversations that can result in knowledge sharing and sales. This scenario is exactly the case in this story where it has turned out that there are two world news about IO-Link in the same house.

Two IO-Link World News in the Same Office Building

At GPower, we are part of a larger office community at Point Nordic in Hinnerup near Aarhus. This is also the case for Wika resulting in great news within IO-Link.

While Wika is behind the world’s first IO-Link pressure sensor with 360° LED status display (Wika A-1200 IO-Link 1.1), GPower has the world’s first IO-Link Toolkit for LabVIEW and TestStand.

How Is It Revolutionary?

The revolutionary element about Wika’s product is that it’s the first IO-Link pressure sensor with a 360° LED status display (see picture). A product that enables operators and repairers to quickly see if everything is OK or if problems need to be solved.

If a green signal is displayed, everything is OK. When a yellow signal is displayed, a critical condition has occurred, and when a red signal is displayed, a definite error is the case. You can use an IO-Link command to make the status LED flash, so you can easily find the device you want to work with in a setup with many devices.

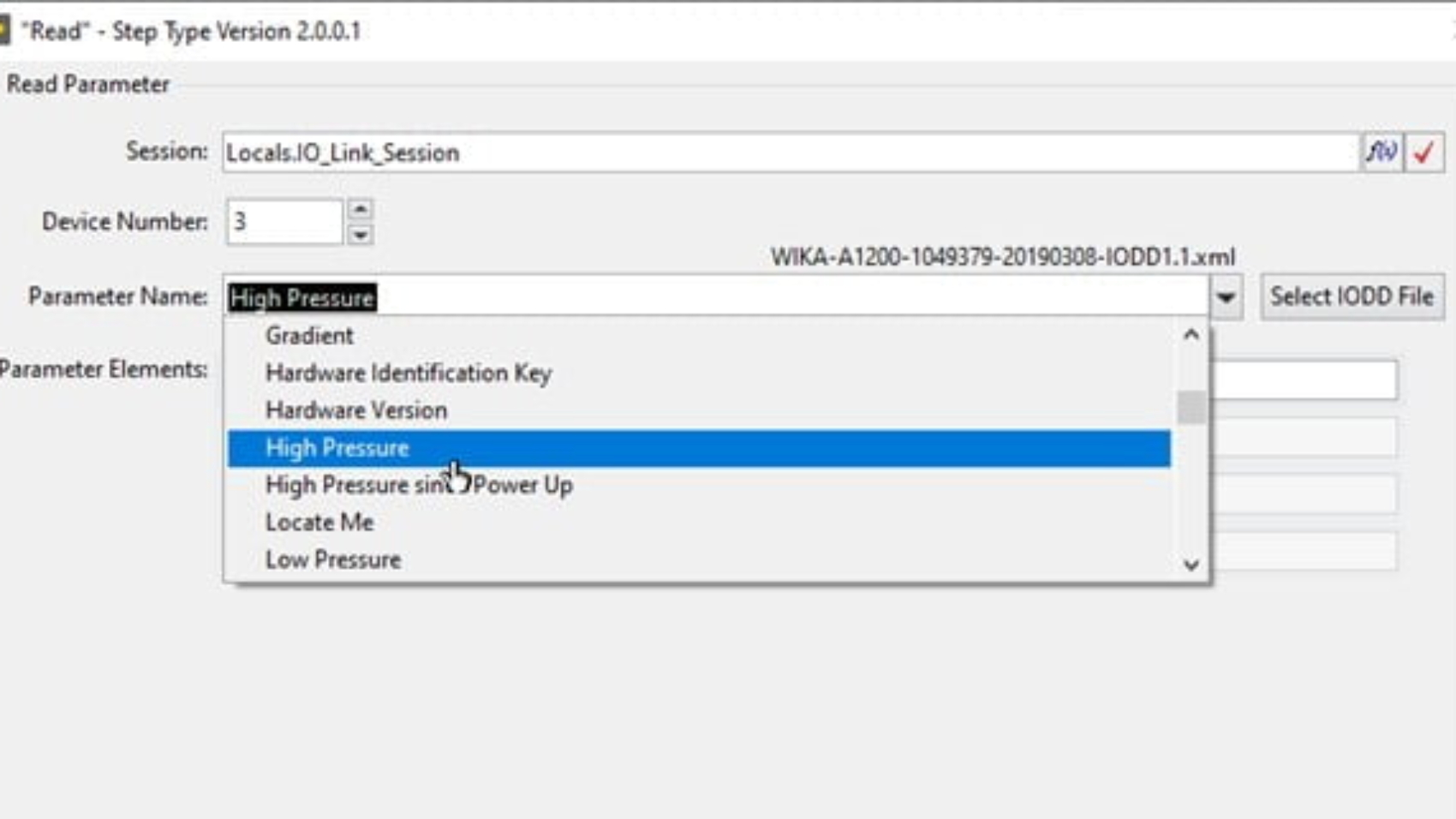

The revolutionary thing about GPower IO-Link, on the other hand, is that the product enables you to easily and quickly connect your IO-Link devices to NI’s tool chain. By simply installing a toolkit, GPower IO-Link provides access to data from more than 30,000 devices in the LabVIEW code. In addition, we have taken our own medicine by using our IO-Link LabVIEW Toolkit to build IO-Link step types for TestStand.

“During the development of GPower IO-Link, we went to great lengths to obtain various IO-Link compatible devices to test our product. It was only after the release of the first version that we accidentally discovered that Wika, who is housed in the same building as us, has IO-Link units in their portfolio. I hope that we can help each other finding areas of application for our products in the future,” says senior specialist at GPower, Jens Christian Ø. Andersen.

![GPower Is Looking for a Software Developer! [LabVIEW & TestStand]](https://gpower.io/wp-content/uploads/2022/03/bliv-udvikler-hos-gpower-labview-teststand-1700x956.jpg)