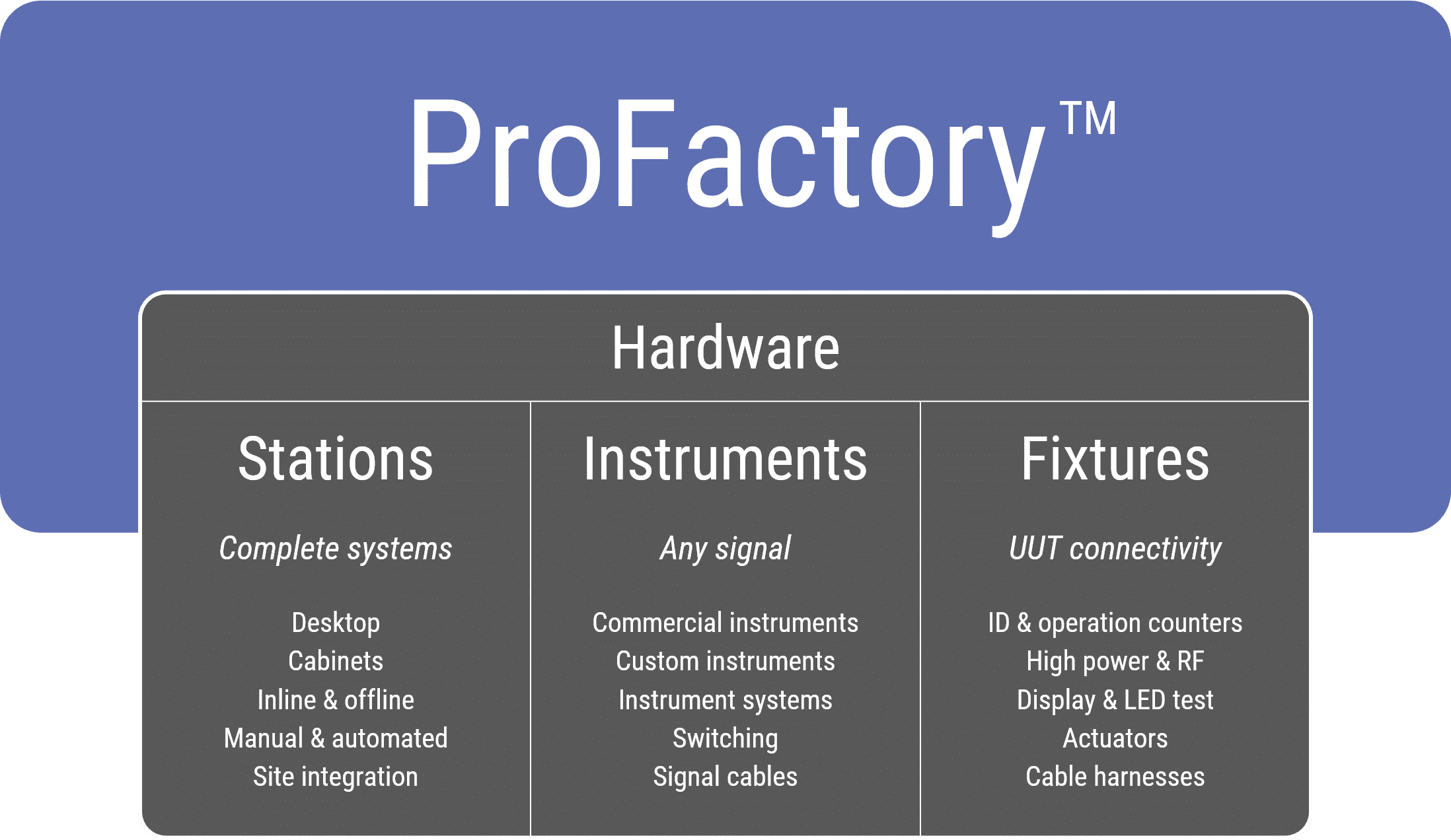

GPower ProFactory

A modular and scalable test system for all kinds of test execution

What Is ProFactory?

ProFactory is an all-inclusive test and automation solution for production facilities, R&D departments, and laboratories. A software and hardware platform that can be implemented on a single computer or scale to support a global corporation.

ProFactory converts your knowhow and existing hardware into modern pieces of test equipment, controllers, or automation devices. ProFactory stations are network enabled, centrally managed and remotely supervised, they support manual or semi-automatic operation by human operators, and they can be fully integrated with automated inline or robotic controlled environments.

ProFactory is standardized to offer you all the professional features you wished you had the time to implement yourself, yet flexible enough to fit your present and future needs perfectly. ProFactory will save you time and money from first implementation and every day you use it.

Why ProFactory?

1: Save Time Every Day by Automating Your Test Operations

Saving time is the most important metric to stay competitive with increasingly rapid changes to requirements. ProFactory saves you time in all operations; The test developer gets you ready for test faster, both with new products and with variants of existing ones. The test technician spends less time on planned and unplanned maintenance, leaving your equipment more time for actual production.

Your stations are much more flexible which allows for higher equipment utilization, less downtime, and more choices moving functions around in your factory. Your operators are guided and have flexible execution options at their disposal which leads to fewer errors and more efficient station use.

2: Save Money by Standardizing without Sacrificing Flexibility

Maintaining your own custom equipment is expensive. You alone pay for every feature development and perform all running improvements yourself, you are responsible for custom training, and you often need to stock many different spare parts.

The result is often inefficient equipment, wished-for features are never implemented, and you live with problems that aren’t really solved because it’s too time-consuming and expensive to do much more than just the most important. By standardizing your equipment you share these expenses with many other people. And with ProFactory you can standardize without sacrificing flexibility. That’s the game changer.

3: Improve Your Product Quality by Testing Correctly Every Time

ProFactory governs many aspects of your test stations which have direct impact on your product quality. You are much less likely to run a wrong test or to run with wrong test parameters, ProFactory can reduce negative effects on your products when retesting, you can take full advanavailabletage of instruments and tracing even when testing prototypes and running in products, and additional insights are if you experience batch problems for instance.

4: Never Lose Data again with Automatic Synchronization and Complete Trace History

ProFactory documents and traces all important aspects of your tests automatically, from environment parameters to a complete changelog. With guided operation, central configuration management, and synchronization your test quality is ensured, and with remote supervision and central result collection you are certain to not lose data ever again.

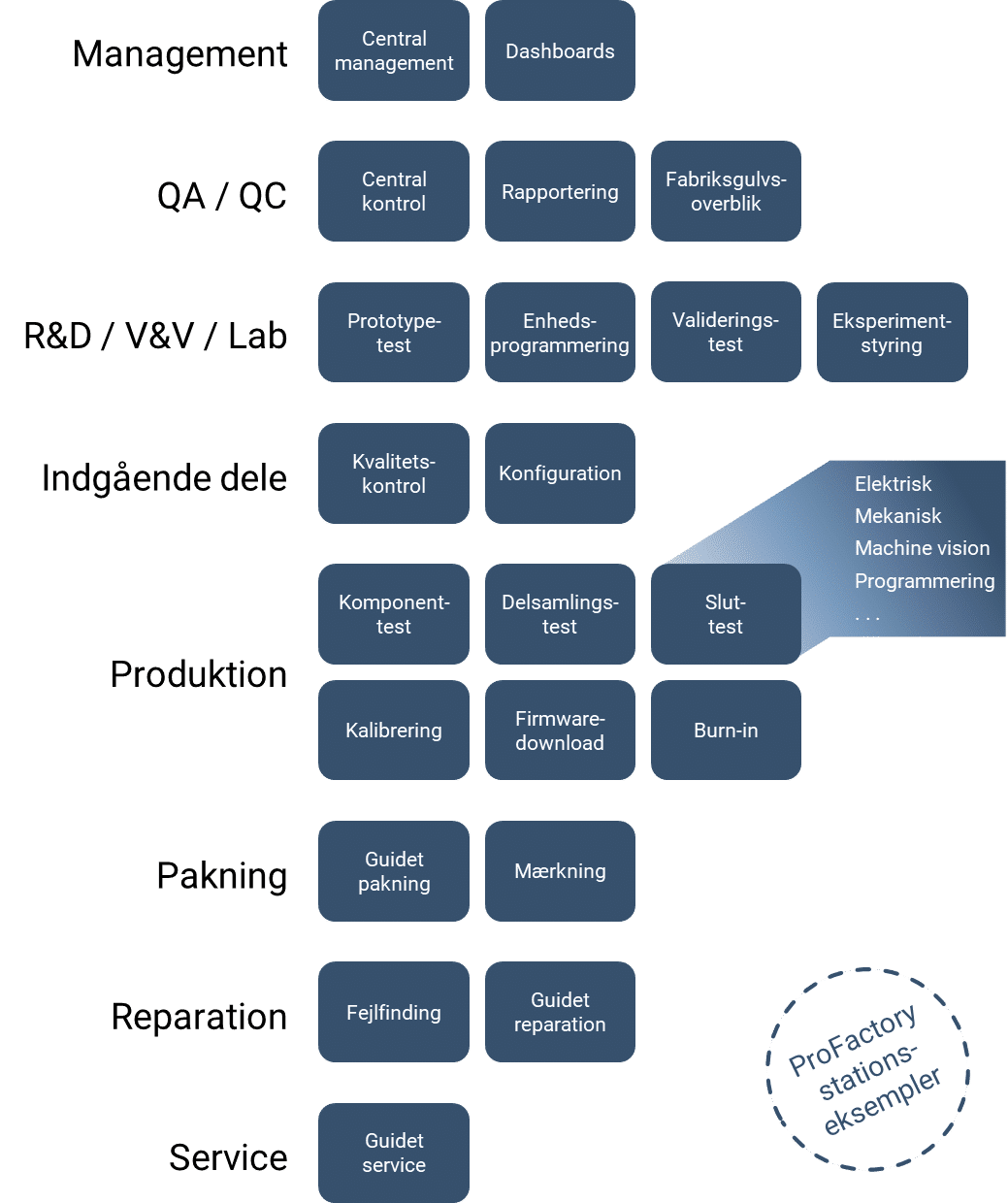

How to Use ProFactory? Application Areas

To let you create, manage, and synchronize ProFactory configurations the ProFactory software components Supervizer, Devizer, and Provider are installed on each computer that is part of your ProFactory network. On functional stations we also install the test management system TestStand by National Instruments, which integrates seamlessly with ProFactory. With this standardized and powerful software we can build any functional station for manual or automated use (see some common application areas below).

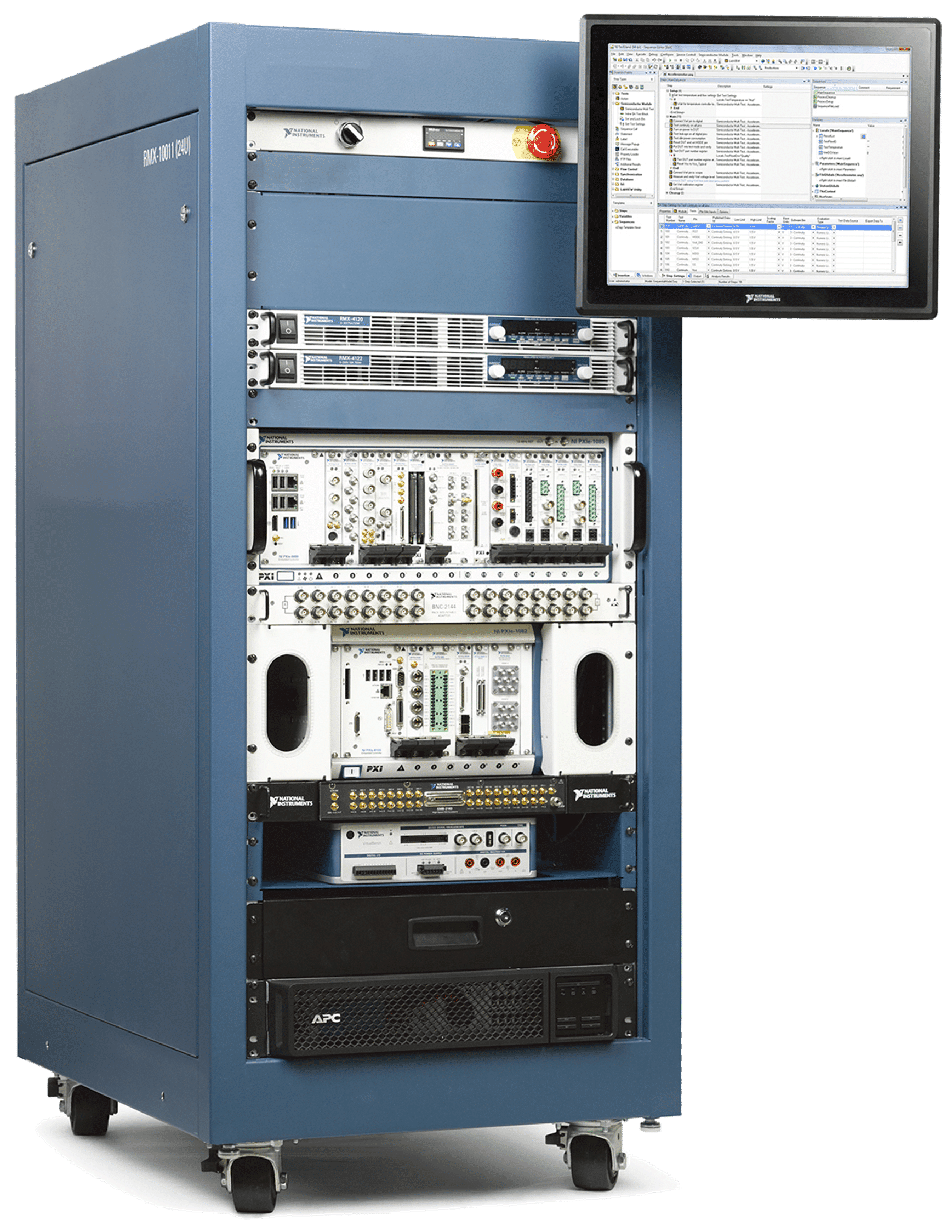

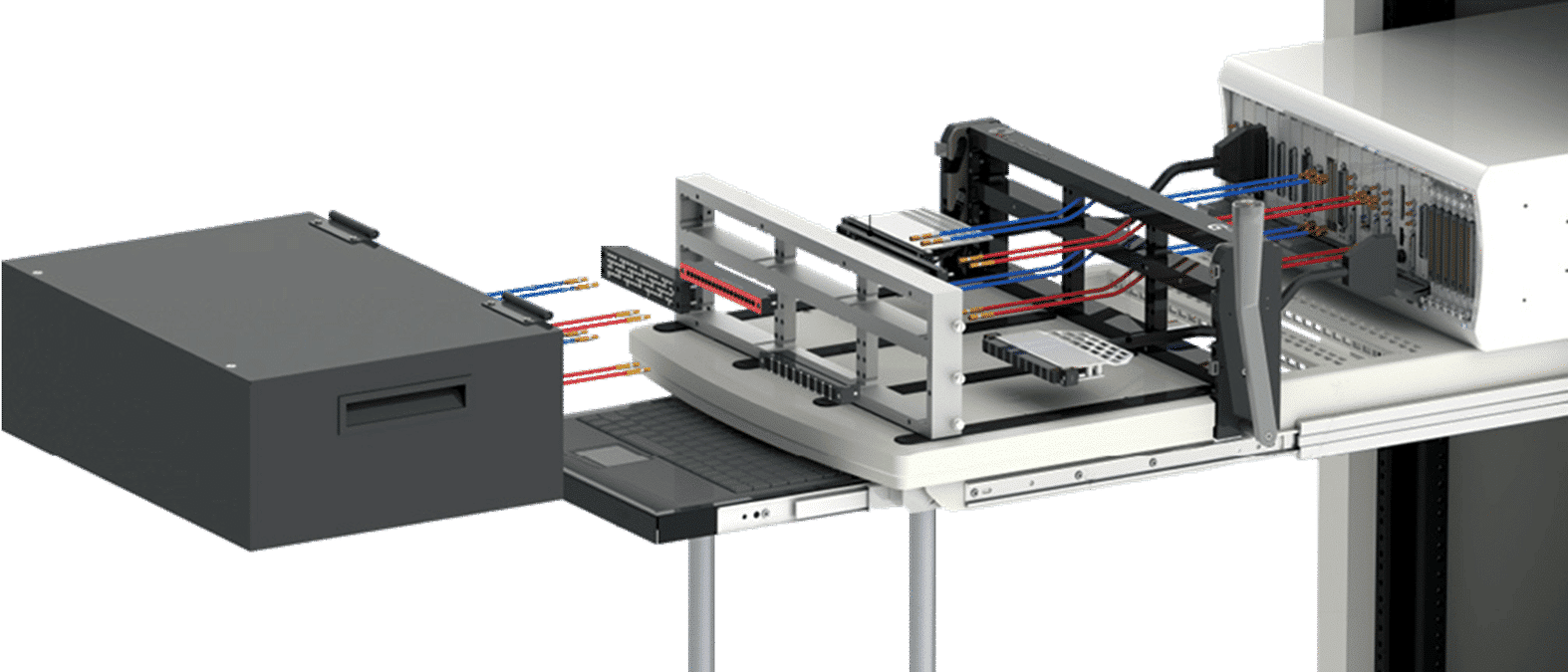

Some automation jobs require only a computer, while others require more hardware such as cabinets with instruments and control systems, and perhaps scanning equipment and interfaces to other devices or to your products. We can supply a ProFactory station for any automation application.

An Extract of Use Cases

Do you have many test stations with its own test system?

Many manufacturing companies experience that the number of test stations increases concurrently with the number of products – and often with its own test system. This makes the test execution very complex and result in huge challenges in terms of version control. The result is often that developers spend all their time maintaining existing systems and no time when it comes to optimizing the test execution.

With ProFactory, you get a common framework where you easily can manage the test sequences. The test stations are automatically synchronized with a common database.

Use modular tests to reuse your test stations in different contexts

When handling complaints, a test of the alleged error is almost always included. Sometimes, it can be done with a visual inspection, while at other times it requires a more thorough test of the electronics. Most often, you will be able to reuse a test station but if the test station is not flexible, it can become a major challenge.

The solution could be to use modular tests where an operator is able to select parts of the test to be executed. In this way, you save time regarding test execution, reduce test sequence maintenance, and avoid having to develop a new test station.

Is it hard to handle test stations distributed in several locations?

In a modern enterprise, the production is often distributed in several locations and often in several countries. Therefore, it can be difficult to ensure optimal cross-border test execution, as the environment can be difficult to replicate, just as it can be difficult to obtain data to document the differences.

With ProFactory, all relevant data is automatically logged to one or more databases that are easily accessible all over the world. This makes it easier to identify parameters that influence the outcome of the test but also to optimize the test execution.

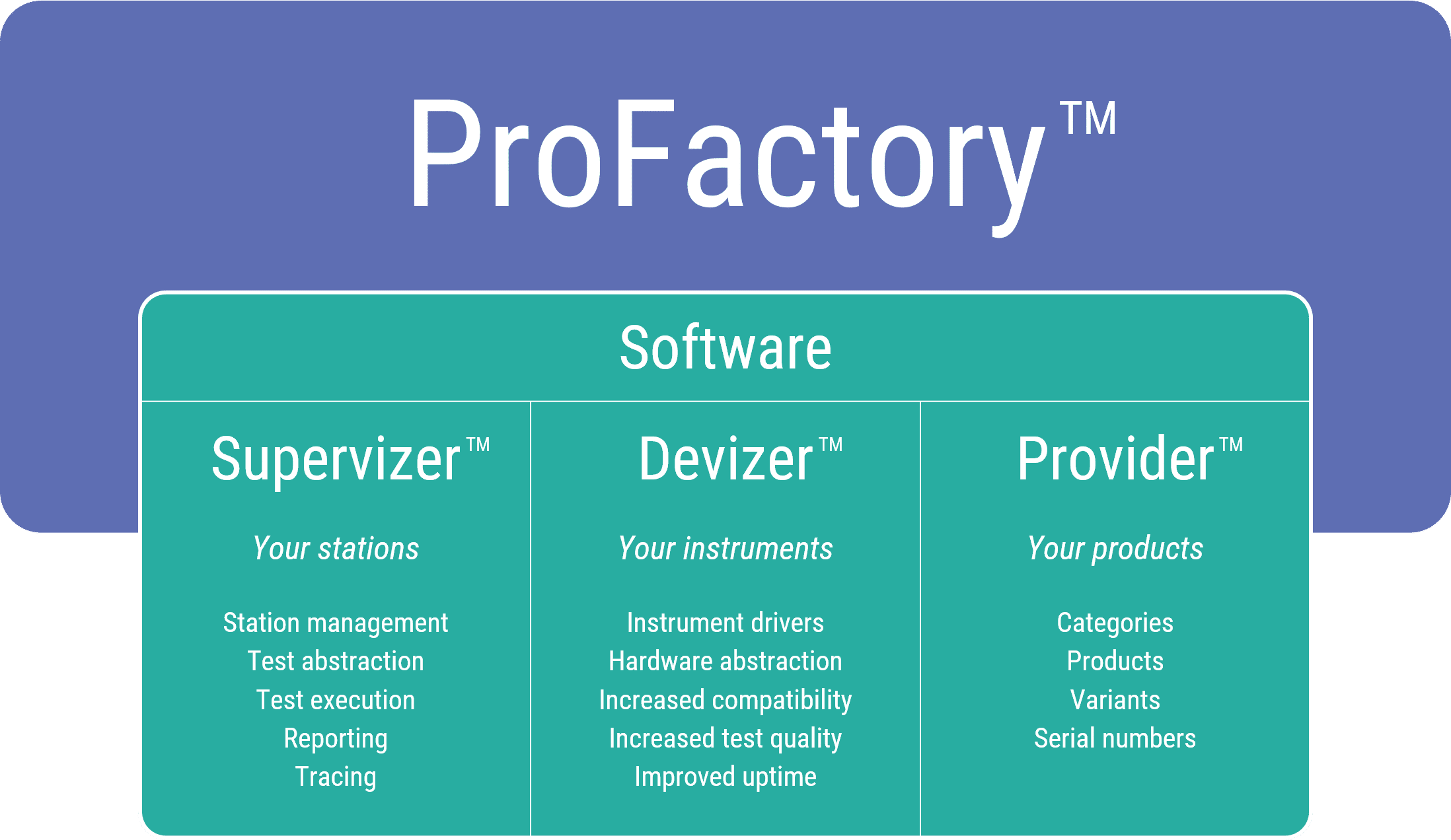

ProFactory Software

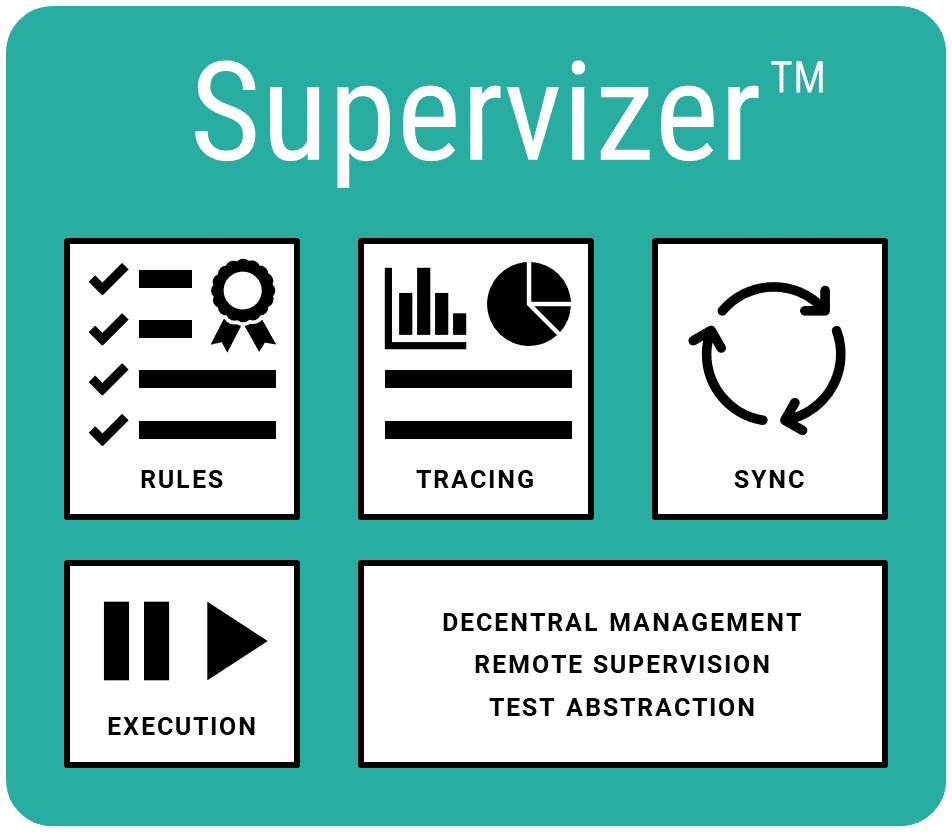

What Is Supervizer?

Supervizer ensures you do your test processes right and it maximizes your station uptime and equipment value. Supervizer does this by managing your stations and test configurations to make sure you lways run the right test with the right parameters.

Supervizer also offers advanced control options such as partial testing and suspend and later resume of tests, it enables deep tracing of your test process and test environment, it offers central configuration and automatic result collection, and it offers remote supervision of your stations.

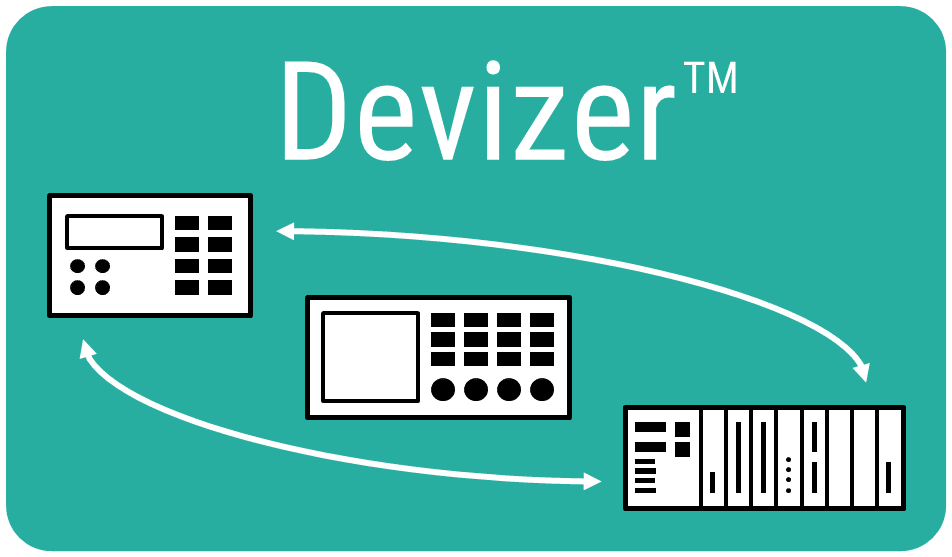

What Is Devizer?

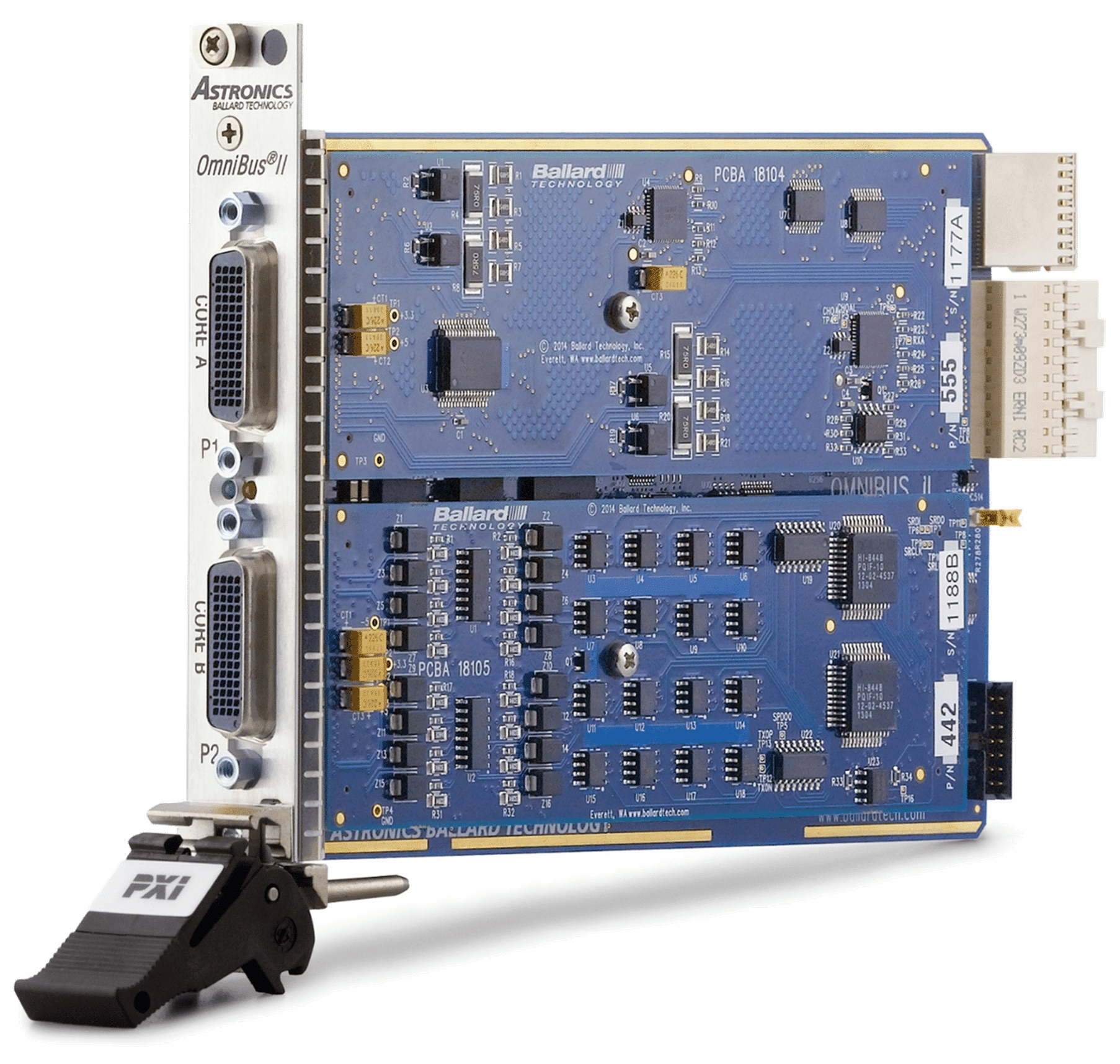

Devizer is an intelligent instrument driver that makes it possible to create one test sequence and use that for all product variants with different hardware on different test stations.

Devizer offers a unique hardware abstraction strategy of abstracting on functions and channels instead of on instrument type. With features such as test requirements validation, instrument tracing, and parameterization of instrument properties, Devizer instrument drivers offer unique value and are a perfect fit for use in test sequences created with the standard test management software NI TestStand. Create Devizer instrument drivers function by function yourself or acquire ready-to-run Devizer drivers from GPower.

What Is Provider?

Provider is the software component that lets ProFactory identify and describe your unit under test (UUT) in a standardized fashion. A physical UUT must always have a serial number. The UUT may be a variant of a product and the product may be part of a category, but variant and category are optional.

ProFactory Hardware

Stations

Instruments

GPower can supply any commercial instrument on the market: Measurement devices, signal generators, power supplies, controllers, industrial interfaces, communication devices, programmers, etc. We have the knowhow to help you select the right instrument. We can supply pre-built Devizer drivers for many common instruments or build one if a driver doesn’t already exist.

Fixtures

Fixtures are typical UUT connectivity components and prime candidates for platform design with ProFactory. Some of our key fixture features:

- Fixture identification

- Fixture connectivity and action counters

- Fixture temperature monitoring

- In-fixture UUT identification

- In-fixture instruments and device programming

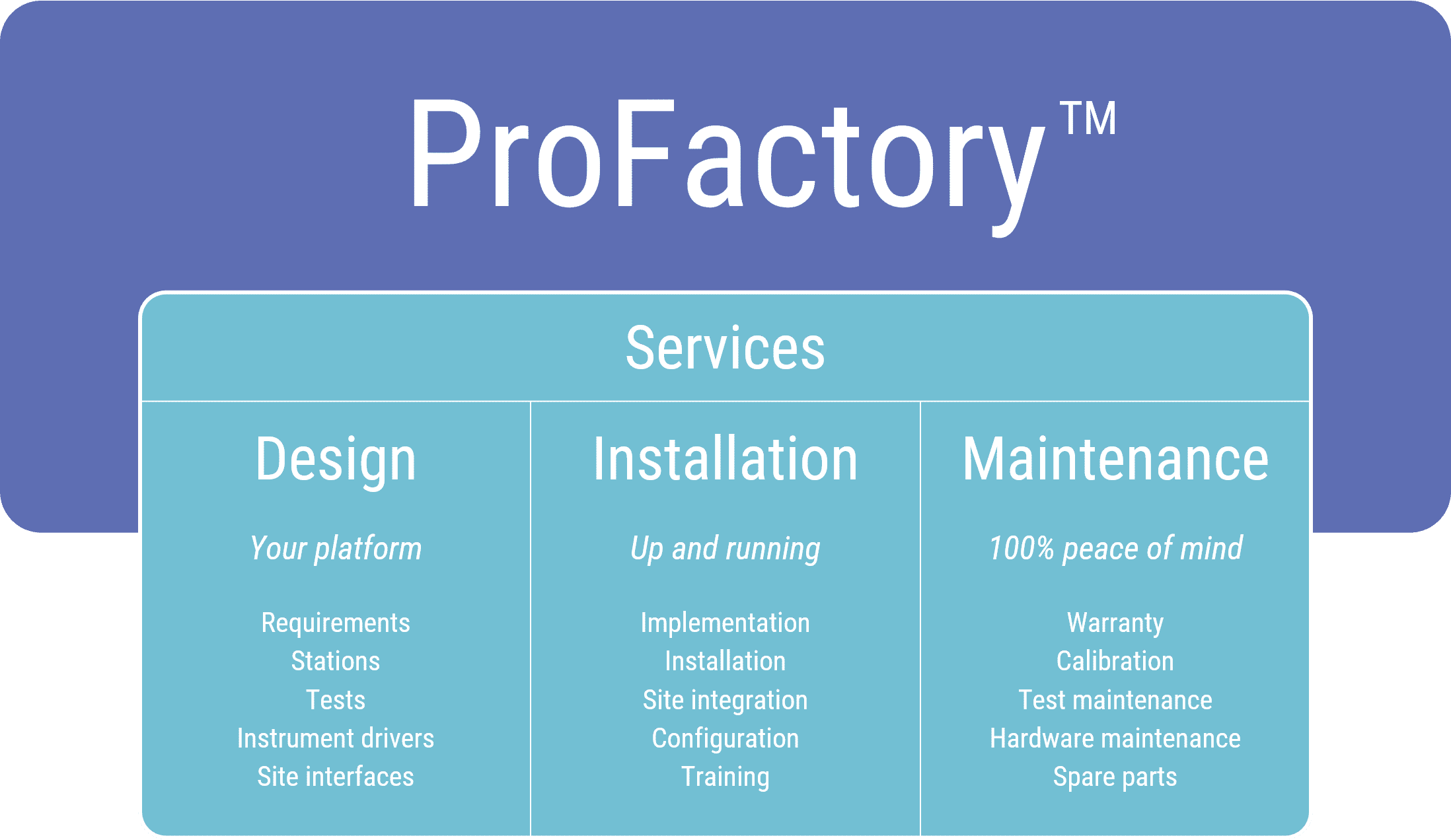

ProFactory Services

Want to Know More?

Want to know more about price and functionality? Call us directly on +45 5190 5790 or submit a form. We will get back to you in 24 hours.